Turbo has industry-leading CFD technology

1. Turbo Research Institute has mastered a core set of Turbo's own CFD technology that combines theory and practice. This technology has been very mature and accurate after many years of repeated engineering applications. In addition, by combining with its own internationally recognized precision laboratory, it has achieved hundreds of repeated comparisons between theoretical values and experimental results, and accumulated valuable experience data.

2. Turbo CFD capability is an important R&D capability of Turbo Research Institute, with high reliability of calculation results and fast calculation process. Through the full range of product common module systems, it can quickly customize for customers while reducing the mold development cost of new products, achieving customization while ensuring economy.

Turbo CFD technology success case

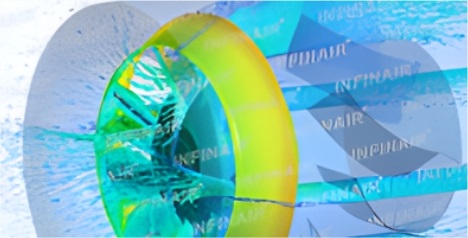

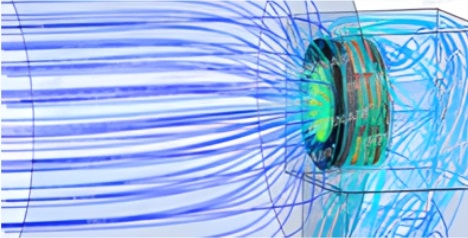

1. Turbo's products are generally systematically developed and optimized through CFD technology, which is the source of Turbo's ability to provide customers with more energy-saving, efficient and low-noise products. The attached figure shows the process of aerodynamic performance simulation we did for Turbo full mixed flow blower, a new box blower of Turbo, and a centrifugal blower of Turbo.

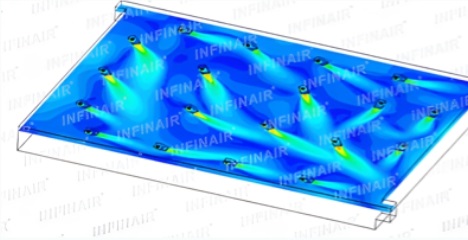

2. In terms of parking garage ventilation system optimization, we have successfully developed a new series of centrifugal induced fans with high static pressure and long projection distance, and provided guidance for the layout of customers' underground garage ventilation systems. The attached figure is a flow field layout simulation we conducted for an underground garage.

CFD flow field pressure and velocity distribution diagram of the patented full mixed flow fan (process display)

Numerical simulation technology CAE

1. Numerical simulation is an application of Computer Aided Engineering (CAE), mainly CFD and FEA two core technologies.

2. During the design stage, the Toupu Research Institute fully calculated and repeatedly adjusted the material types, material thickness, structural form, and processing methods used to ensure that the product parts can withstand various forces during operation, ensure the long-term reliable operation of the fan, and ensure that the product cost is reasonable

3. The final product solution has been verified by the Toupu laboratory for reliability, and failure analysis and life extension analysis have been conducted on the products that have undergone aging experiments, and clear conclusions have been drawn, thereby improving product reliability for customers while reasonably saving equipment investment.

Toupu has mature FEA technical capabilities

Data and experience

Toupu has accumulated a lot of data and experience in the process of FEA technology practice for many years, and is very suitable for the actual physical properties of materials commonly used in the Chinese market.

Precision design

Toupu Research Institute fully calculates and repeatedly adjusts the material types, material thickness, structural form, and processing methods used during the design stage, ensuring that the product parts can withstand various forces during operation, ensuring the long-term reliable operation of the fan, and ensuring that the product cost is reasonable

Precise solution

As a "virtual laboratory", CFD can quickly iterate, save costs, and shorten the R&D cycle. It is a powerful tool for efficient and reliable fan R&D and non-standard customization, and can also provide precise solutions for ventilation system optimization.

Toupu FEA technology success case

1. The attachment is a display of the process of Toupu Research Institute analyzing a customized fan for a customer. According to the inherent vibration characteristics of the customer's system, Toupu Research Institute conducted a vibration modal analysis on the entire customized fan to achieve structural optimization, avoid resonance with the system, and ensure long-term reliable operation of the fan.

2. To analyze the stress and deformation of a motor bearing of a certain model of Toupu during operation, Toupu Research Institute conducted a modal analysis based on FEA technology.

R&D team and strength

Toupu Research Institute

The company has more than 80 R&D design and process personnel, including many engineers with middle and senior professional titles and experienced technicians in fan HVAC, mechanical design and electrical engineering. The professional configuration is reasonable and the personnel are experienced, which ensures the advanced nature of product design.

Toupu Research Institute always adheres to the basic concept of "reliability, convenience and novelty" of products as the basic concept of R&D and design. Under the guidance of this spirit and concept, the research institute team has achieved fruitful results, obtained more than 100 patent certificates and many honors, making Yingfei Fan always the leader in the industry.

With "product life cycle" as the main line, it is fully responsible for the management of all the company's products

User demand research

Product planning and feasibility analysis

Product development and manufacturing

Testing and certification

Product listing and promotion

Customer feedback and product upgrade

Product delisting or iteration

Venturi selection software

Professional selection software

Covering all conventional products of Toupu, achieving "fast, accurate and reasonable" selection quotation!

Wide selection parameters

Wide parameter range, accurately matching customer needs

Diversified configurations

Inlet and outlet air direction/surface treatment/power supply/motor type.…

Optional accessories

Vibration absorber/mounting flange/protective net/dome/rain cover.…

SDR customization

SDR process is convenient and solutions can be quickly formulated to meet customers' special needs

Parameter requirements

• Combine the customer's operating conditions and the purpose of the fan to select the model, and accurately locate the model in the huge database of the Infrared selection software

• Consider multiple parameters, comprehensively consider parameters such as static pressure ratio, speed, noise, motor power, outlet wind speed, and select the product with the best cost performance according to customer needs

• The selected product will be configured and accessories will be selected to complete the selection and provide a quotation

Panshuo fan creates more value for users

Panshuo fan creates more value for users